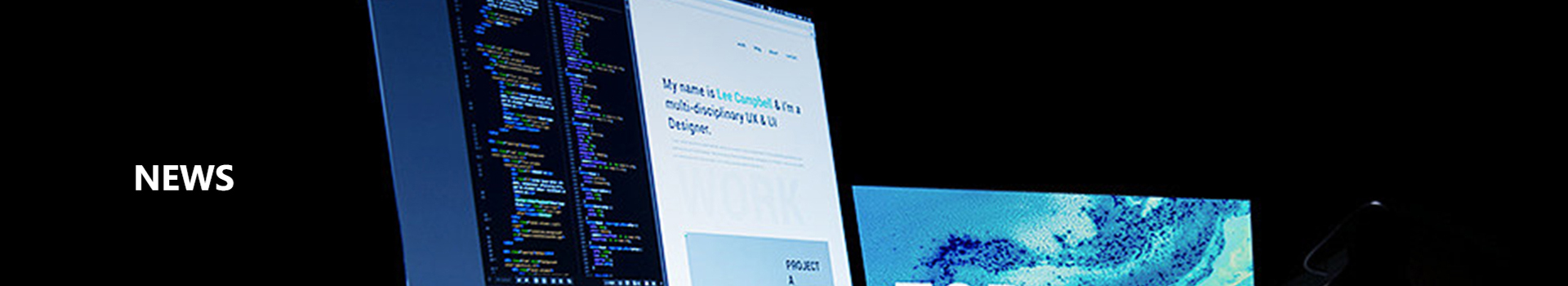

About the structure of automatic glue spraying machine

Automatic glue spraying machine is a kind of automation equipment specially designed for automatic spraying of water-based glue, which is mainly divided into two major parts: hardware and software.

The hardware part is mainly composed of four axes (X-axis, Y-axis, Z-axis, U-axis) and servo motors to control the axis movement, the software part is a programme control system, the whole machine operation is through the programme to control the axis movement to cooperate with the completion of the entire spraying action is completed.

Spray machine software from the structure of the points, mainly composed of three parts: the underlying software, control process implementation and user interface.

1, The underlying software to achieve the definition of the I / O settings, logic settings, four axes of motion, starting speed, acceleration, running speed, back to the mechanical home mode and other parameters of the configuration, easy to debug the hardware. At the same time also provides a wealth of functions to facilitate the upper software call, so that in the upper software design can focus on the implementation of the spray function.

2, Control process layer according to the spraying track and preset parameter configuration, automatic execution of the control process.

3, User interface layer is used for human-machine interaction to operate the machine directly during demonstration, editing of preset parameters and manual single-step operation, so as to ensure the smooth execution of automatic operation. At the same time also provides a variety of abnormal conditions, in order to facilitate the diagnosis of machine failure.

The automatic glue spraying machine adopts international advanced computer control technology, which is very convenient to operate and suitable for spraying operation of materials in multiple industries such as footwear, wallets, handbags, luggage, and jewellery.

The main function of the automatic glue spraying machine:

1、Simple operation, can be programmed on the spot by touch screen computer, or on the computer through CAD/CORELDRAW and other applications Ranjian programmed into PLT format and then downloaded to the machine, easy to learn and easy to understand.

2、High speed, using a bridge-type platform structure, you can work while discharging materials, spray glue speed is 5-6 times faster than manual.

3, up to four-axis linkage, in addition to forward and backward, left and right movement, but also three-dimensional, oblique, solitary surface on the glue.

4, High precision, even spraying surface, no push glue, dead glue phenomenon.

5, the glue barrel is completely sealed, is the glue will not dry solid. Reduce the waste at the same time to avoid the dry solid and lead to the volatilisation of toxic gases on the pollution of the working environment.

6, Applicable to a wide range of glue, such as white glue, universal glue, PU glue, hot melt glue.

7, Working range is large, can spray 1000mmx600mm.

8, Environmental protection and energy saving, air extraction system, can be sprayed when the glue on the odour and mist filtering treatment.

- Previous:Kui Long Shoe Machinery signed a 5 million large order in Qingyuan

- Next:Already the last article